An ISO certified machining shop located in Lugano, Switzerland, “Bernasconi metal-constructions SAGL” specializes in designing and manufacturing cantilever roofs, intermediate floors, stairs, metallic carpentry for a wide variety of verticals. “We are a small enterprise of 9 employees that does a little bit of everything,” says Founder Davide Bernasconi, who started the company in 1986. “The sector isn’t as big as it used to be. So we diversified. We got into other areas like production machining and fabrication. And we also do work in automotive, plastics, defence, consumer. Really, we do it all”.

Business challenge

The company, located in Switzerland, strongly suffered the change in the exchange rate among Euro and Swiss Franc that lowered their price competitiveness of about 20%.

“Some of our typical customers started buying products from the nearby Italy that is able to provide more competitive offers. The result is that we have to cope with periods with very high production saturation and periods with a very limited one”.

Solution

With the differentiation among several industry sectors becoming the key to survive, MANUSQUARE gave Bernasconi Metal-Constructions the possibility of boosting differentiation and finding customers requiring products that they can manufacture.

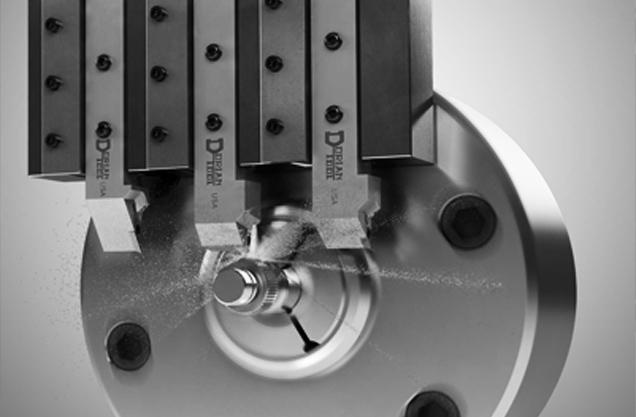

“We have 2 CNC machines in our job-shop that, thanks to MANUSQUARE, are now working all the time. We can exploit the flexibility of the platform allowing us to take orders only when we have a lack of production.

The effort is minimized since the platform already provides the CAD and all the information related to the manufacturing, we just have to order the material, put it in the machines and once ready, send the products to the customers. MANUSQUARE is an hassle-free life jacket for periods of low production!”

Disclaimer:

The above use case is a mere theoretical and dramatized example of the foreseen features of the platform.